1. Silinda e cheselitsoeng ke eng?Moqomo o cheselitsoe ka ho toba ho li-caps tsa ho qetela 'me likou li cheselitsoe ho moqomo.Thepa e ka pele ea rod hangata e bolt kapa e kentsoe ka har'a moqomo oa silinda, e lumellang kopano ea piston rod le li-rod seals hore li tlosoe bakeng sa ts'ebeletso.Li-cylinders tse cheselitsoeng tsa hydraulic li na le melemo e mengata ho feta li-cylinders tsa lithupa.Le hoja li-cylinders tsa li-cylinders li ka ba theko e tlaase ho li etsa, hangata li nkoa e le lintho tse "ntle ho sethala" 'me li na le likhetho tse fokolang ho latela mokhoa oa ho ikhethela.Hape ha li tšoarelle nako e telele ho feta li-cylinders tse cheselitsoeng.Li-cylinders tsa 'mele tse cheselitsoeng li ka etsoa ka tloaelo bakeng sa lits'ebetso tse ikhethileng.Li-cylinders tse cheselitsoeng li boetse li na le liphutheloana tse phahameng tsa tiiso, tse ka thusang ho eketsa nako ea bophelo ea cylinder 'me e ka ba molemo ha cylinder e tla sebelisoa libakeng tse kenyelletsang litšila le boemo ba leholimo.Ka bokhabane, lisilindara tsa 'mele tse cheselitsoeng li na le liprofaele tse tlase ho feta li-cylinders tsa melamu ea thae mme li ka ntlafatsa ponahalo ea thepa eo e sebelisoang ho eona.Kaha li tšesaane ho feta tse lekanang le lithupa tsa thae, li-cylinders tse cheselitsoeng tsa hydraulic li sebetsa hantle lits'ebetsong tseo sebaka se leng sona.

2. Mokhoa oa ho laola boleng ba welding nakong ea tlhahiso ea boima?

Thepa ea ho Welding;Lokisetsa sampole ea tjheseletsa ka tieo ho latela litlhoko tse reriloeng esale pele: Ho futhumatsa, ho cheselletsa, ho boloka mocheso le ho lokisa sampole ea welding.Le ho etsa karete ea ts'ebetso ea welding ho fana ka motheo oa ho kengoa ts'ebetsong ha tjheseletsa;Lisebelisoa tsa ho tjheseletsa, terata ea welding le khase ea welding ke lisebelisoa tse ts'oanang, ts'ebetso e tsitsitseng, bohloeki bo phahameng ba khase, le likarohano tse nepahetseng;Motho ea chesellang, o hloka ho ba le setifikeiti sa welder;Teko ea welding, joalo ka tlhahlobo ea matla a weld bead le tlhahlobo ea ultrasonic ho lekola boleng ba welding.

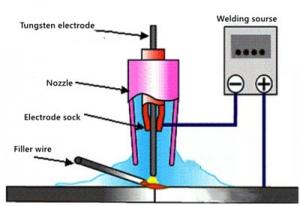

3. Khase e sirelelitsoeng welding e ka aroloa ka tjheseletsa e sirelelitsoeng ka khase e sa sebetseng (TIG welding), welding e sebetsang ka khase e sirelelitsoeng (welding ea MAG) .Ho hlakile hore argon e sebelisoa hangata ka lebaka la theko ea eona e tlase, ka hona, welding ea tšepe e sirelelitsoeng ka khase ea inert e boetse e tsejoa e le argon arc welding.Tungsten inert gas welding ke ts'ebetso ea welding eo ho eona tungsten kapa alloy ea tungsten e sebelisoang e le lisebelisoa tsa elektrode, 'me arc e hlahisoang lipakeng tsa elektrode le thepa ea motheo e sebelisetsoa ho qhibilihisa thepa ea motheo le ho tlatsa terata tlas'a tšireletso ea khase ea inert. .

TIG, eo hape e tsejoang e le Gas Arc Welding (GTAW), ke mokhoa oa ho etsa Arc pakeng tsa electrode ea Tungsten le tšepe ea motheo tlas'a tšireletso ea khase e sa sebetseng e le hore tšepe ea motheo le lisebelisoa tsa terata li ka qhibiliha ebe li kenngoa.E kenyelletsa welding ea DC TIG le welding ea AC TIG.

DC TIG welding e nka mohloli oa matla oa ho tjheseletsa oa DC arc e le mohloli oa matla a ho cheselletsa, o nang le matla a mabe haholo le lisebelisoa tse ntle.E sebelisoa haholo-holo bakeng sa ho tjheseletsa tšepe e sa hloekang, titanium, koporo le alloy ea koporo.Mohloli oa matla oa ho tjheseletsa oa AC TIG o tsoa ho AC arc, 'me anode le cathode ea lisebelisoa tsa motheo li fetohile.EP polarity electrode overheating e ka tlosa lera la oxide e tlase, e sebelisoang haholo bakeng sa aluminium, magnesium le welding e 'ngoe ea alloy.

Ha TIG (GTAW) ts'ebetso ea ho tjheseletsa, welder e ka ba sethunya sa welding ka letsohong le le leng le terata ea ho tjheseletsa ka letsoho, e loketseng bakeng sa ts'ebetso e nyenyane le ho lokisoa ha letsoho.TIG e ka chesetsoa hoo e ka bang litšepe tsohle tsa indasteri, e fana ka sebopeho se setle sa welding, slag e nyane le lerōle li ka sebelisoa haholo ka poleiti ea tšepe e tšesaane le e teteaneng.

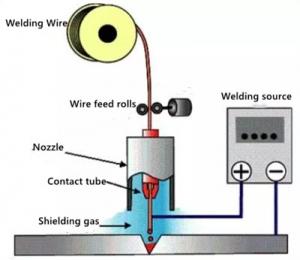

MAG (Metal Active Gas) Welding e sebelisa CO₂ kapa motsoako oa argon le CO₂ kapa oksijene (Ac Active Gas).Ka linako tse ling welding ea CO₂ e bitsoa CO₂ arc welding.Lisebelisoa tsa ho tjheseletsa tsa MIG le MAG li tšoana ka hore li ka fepeloa ka ntle ho toche ka mochini o fepelang oa mohala o ikemetseng 'me li loketse bakeng sa welding ea othomathike, re sa bue ka welding ka letsoho.Phapang e kholo pakeng tsa bona e lutse ka khase e sireletsang, ea pele e sirelelitsoe ka kakaretso ke khase e hloekileng ea argon, e loketseng bakeng sa ho cheselletsa litšepe tse se nang ferrous;MAG tjheseletsa haholo-holo e sebelisa CO₂ khase, kapa argon e tsoakiloeng CO₂ khase e sebetsang, e leng Ar+2%O₂ kapa Ar+5%CO₂, e loketseng bakeng sa ho cheselletsa tšepe e matla haholo le tšepe e phahameng ea alloy.E le ho ntlafatsa ts'ebetso ea ts'ebetso ea CO₂welding, CO₂+Ar kapa CO₂+Ar+O₂ e tsoakiloeng ea khase kapa terata ea flux-cored e ka boela ea sebelisoa.MAG welding e khetholloa ka lebelo la eona la ho tjheseletsa ka potlako, ts'ebetso e phahameng ea ho qalisa arc, letamo le tebileng, ts'ebetso e phahameng ea deposition, ponahalo e ntle, ts'ebetso e bonolo, e loketseng ho chesehela ka lebelo le phahameng la pulse MIG (GMAW).

Fast e ikemiselitse ho R&D le tlhahiso eali-cylinders tsa hydraulicle litsamaiso tsa haeteroliki, ho sebeletsa bareki le ho fa basebetsi bophelo bo betere.Ho fihlela joale, re se re thusitse bareki ba likete lefats'eng lohle ho fana ka boiphihlelo ba hydraulic cylinder le moralo oa sistimi ka melemo ea tlholisano.

Nako ea poso: Sep-16-2022